First published in Accelerate America Magazine November 2014

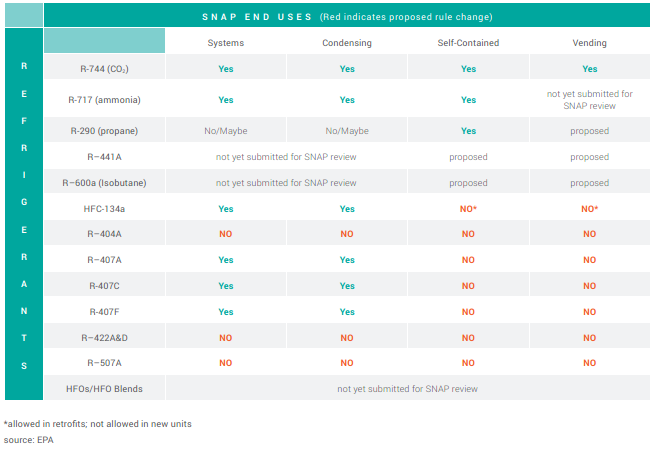

Those who pay attention to the goings-on at the Environmental Protection Agency (EPA) have probably noticed the recent proposal by the Significant New Alternatives Policy (SNAP) program to make it illegal to use certain HFC (hydrofluorocarbon) refrigerants that are potent global warming gases in new commercial refrigeration equipment and retrofits as of January 2016.

Manufacturers of equipment that uses natural refrigerants may be wondering if this EPA proposal represents an opportunity for them. The answer to that question is a definite “maybe,” depending on the type of commercial equipment they manufacture and where they are in the development process.

Manufacturers of commercial refrigeration systems or the components used in these systems are unlikely to feel a direct effect from the proposal. There are still plenty of HFC refrigerants available for commercial systems, such as R-407A and R-407F, so systems manufacturers are not (yet) being forced into natural refrigerants. Manufacturers may see an indirect effect, however, because even though the proposed rule doesn’t directly dictate that end-users must use natural refrigerants, end- users may view it as the EPA’s first step in that direction and interpret this proposal as a not-so-gentle electric shot to their derrières.

Many supermarket end-users have already been investigating natural refrigerant commercial equipment, perhaps even trying them out in a store or two. When asked by their colleagues why they install these systems even though they are currently more expensive than traditional systems, they usually respond that they think it is important to get out in front of the EPA, so that they are ready when the agency starts to phase down or eliminate HFCs. They want to start evaluating natural refrigerant systems at their own pace and influence the designs where necessary to make the technologies work for them. They realize that the first natural refrigerant system they install may not be the cheapest one available, but they are banking on the fact that they’ll work out the kinks and get to the point where these systems make financial sense. They think that starting with natural refrigerant systems now will give them a competitive advantage later when everyone else is forced to make the switch on the government’s timetable.

The equipment manufacturers now working with these end-users will be ahead of the game when natural refrigerants become mainstream. They will have benefited from the expert input from end-users at all stages of the design phase, as well as from valuable feedback from end-users and service technicians on improvements in the ease and cost of installation. They will have gathered proof that natural refrigerant systems reduce costs through energy efficiency gains, decreased line sizes for piping, etc.

Most of the major systems manufacturers saw the writing on the wall that the EPA was going to start to move the market in the direction of lower-GWP (global warming potential) refrigerants. The EPA has not made a secret of its desire to combat global warming, and it hasn’t minced words about refrigerants being one of the opportunities to quickly make major greenhouse gas cuts.

The agency has attempted for the past several years to get the Montreal Protocol to act against HFC refrigerants. They have started an international organization called the Climate and Clean Air Coalition with more than 80 partners around the globe to address HFCs and other potent global warming gases. The EPA’s Green Chill Partnership has been consistently preaching that supermarkets should be using the lowest GWP refrigerant that meets their performance needs. EPA plenary presentations at the Food Marketing Institute’s annual Energy and Store Development Conference have focused on the list of power GWP refrigerants that are available for commercial refrigeration and presented the history of refrigerant use as a series of moves over decades that will eventually lead to the use of very low GWP refrigerants (see diagram). The EPA has held numerous webinars on lower GWP refrigerants that are available for commercial refrigeration and focused on CO2 systems, ammonia systems, and hydrocarbons, which are already in use in U.S. supermarkets. The manufacturers that did not see this coming have not been paying attention.

MORE TIME NEEDED

Take the manufacturers of self-contained commercial refrigeration units as an example. Many of them testified at an EPA hearing in August on the proposed delisting rule that they need more time to convert their equipment to use lower GWP refrigerants. There is no doubt that their R&D process will take several years, as will line conversion at manufacturing facilities and the process to get new equipment tested for safety and certified by a Nationally Recognized Testing Laboratory.

That’s not to say that there aren’t plenty of self-contained equipment companies that saw that the EPA was going to move in this direction. There are several that are ready to supply the market demand for self-contained refrigeration units that use hydrocarbon and CO2. They are ready for January 2016, and they definitely have a competitive advantage over companies that lag behind them.

But isn’t that as it should be in our system that thrives on innovation, smart decisions, and visionary leadership? Should the EPA give more time to companies that failed to see or ignored what was coming? Or is this natural selection at work in our capitalist marketplace? Yes, the free market is cruel. Survival of the fittest makes easy prey of those who don’t change with the times.

Whether the EPA gives more time to self-contained equipment manufacturers that lag behind will depend in part on whether companies that already have this equipment will be able to supply 100% of the demand for that equipment as of January 1st, 2016. If they can’t meet the demand, or if there are too few manufacturers to provide healthy competition, the EPA will likely give others a few years to develop their capabilities.

Even if self-contained commercial equipment manufacturers are given more time to bring low GWP refrigerant equipment to market, companies that are ready now will still have an advantage. End-users don’t want to wait until regulations go into effect to start trying out new equipment. They want to figure out whether units that use hydrocarbons or CO2 save energy, whether size requirements will change, even whether it is possible to use self-contained units to refrigerate all the food in small footprint stores. They want equipment now.

Companies that stop everything to try to fit a lot of R&D and manufacturing changes into a few years will also suffer from the disruption to their business caused by having to focus all their human resources, time, and financial resources to make this switch as soon as possible. During this time, they won’t have any people, energy, or money to focus on much else. In the meantime, companies that are ready now can focus on next-generation technology over the next five years to remain ahead of everyone else. And that may be as it should be.